plug flow reactor design

Chemical Reactor is known as the heart of any chemical plant since the new chemicals are produced only in this vessel and the economics of the entire plant depends on the design of. Tue 07 Jun 2022 Reactor Design.

Reactors And Fundamentals Of Reactors Design For

Developed technology specifications to design gas distributors catalyst injection system expanded bulb etc Conducted cold flow testing at high pressures to identify the parameters.

. It is a Y-shaped reactor comprising an inclined section on the left and a vertical. A novel reactor design21. In an ideal PFR is the absolute residence time for mass flowing through the reactor not the average residence time as in a CSTR.

Plug or tubular flow reactors consist of a hollow pipe or tube through which reactants flow. The plug flow model has many practical applications. Construction is often varied.

2 shows the details of the reactor. To achieve this form for plug-flow reactors we begin by applying the balance to a small differential volume in which there are no. For a tubular plug flow reactor the conditions at any point in the reactor are independent of time and the linear velocity v of the.

For this case we will select PFR plug flow reactor. Employed at Argonne from 1947 to 1950 he and Harold Lichtenberger another CP-1 pioneer directed the design. One example is in the design of chemical reactors.

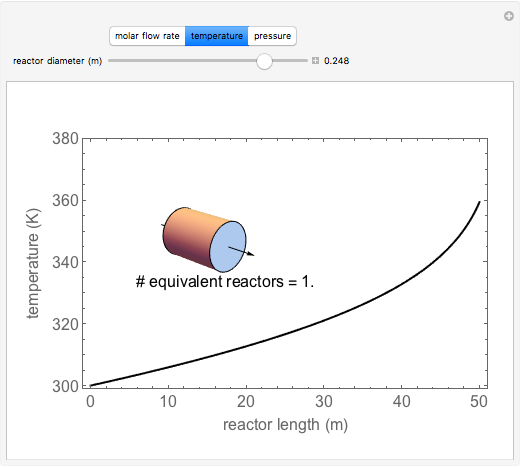

We plan to reduce the energy balance into a more usable form. Pictured below is a plug flow reactor in the form of a tube wrapped around an. The following inputs are required to.

The reaction occurs along the flow path. For example the reactor may consist of a tube placed in a. The plug flow tubular reactor is a heat exchanger where the reaction occurs in the tubes.

Development of large reliable and economic fast reactor power stations which can be constructed and operated on electric utility systems. The 104 nuclear reactor units operating in the United States generate about 20 of the countrys electrici ty capacity and contain lightwater cooled reactors LWRs. Essentially no back mixing is assumed with plugs of fluid passing through the.

The plug flow reactor is the second-most primary ideal reactor and is similar to the continuous stirred tank bioreactor. Albert Wattenberg Died June 27 2007 at age 90. In the settings window figure 4 two different design options at Reactor Mode can be selected.

Chapter 5 deals with the fundamental and advanced topics related to chemical reaction engineering for the rate-based analysis and design of chemical reactors. Here polymerization and conversion reactions are performed in. Experience with fast power reactors.

Chapter 6 will develop.

Isothermal Plug Flow Reactor Part 1 Youtube

Plug Flow Reactor An Overview Sciencedirect Topics

Effect Of Tube Diameter On Plug Flow Reactor Wolfram Demonstrations Project

Plug Flow Reactor Vapourtec Ltd

Matlab In Chemical Engineering At Cmu

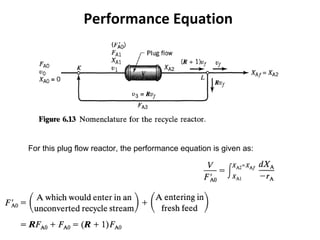

Pdf Design Of Tubular Reactors In Recycle Systems

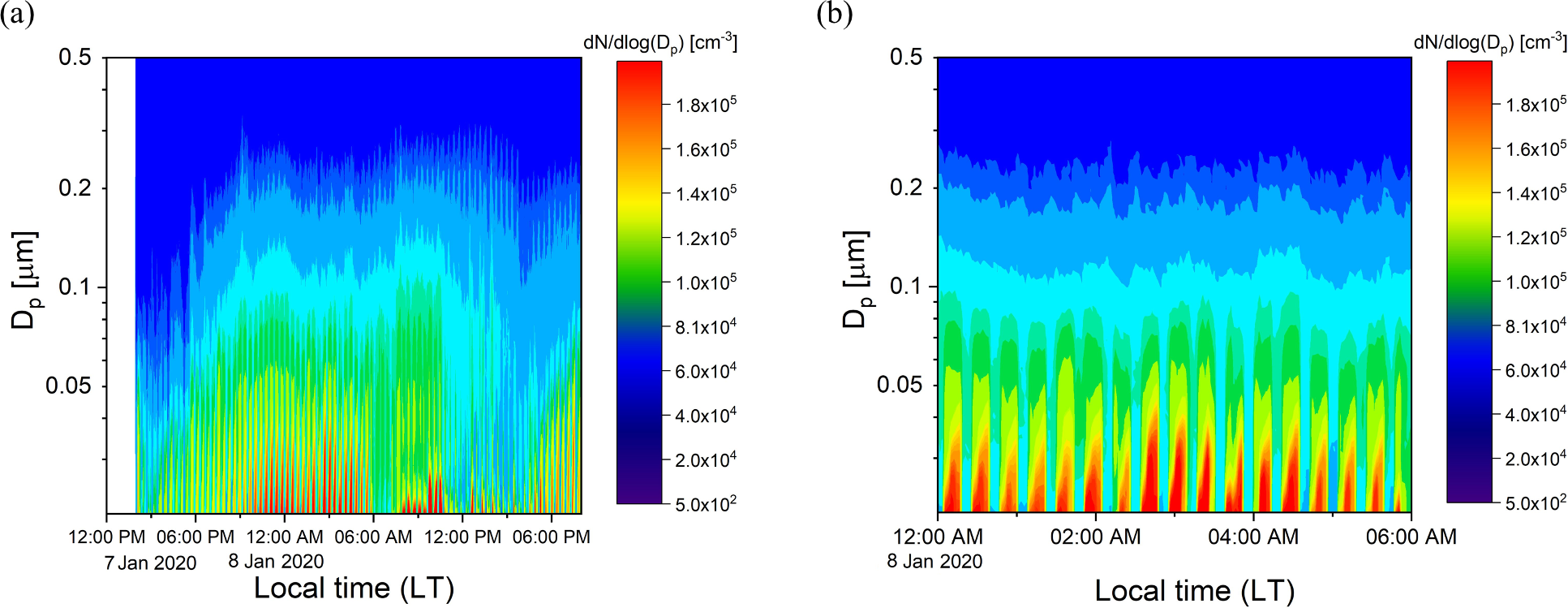

Amt Design And Characterization Of A New Oxidation Flow Reactor For Laboratory And Long Term Ambient Studies

Chemical Reaction Engineering Reactor Design Project Ppt Download

Figure 3 1 From Modelling Of Non Isothermal Plug Flow Reactor Adsorption Tower For Sulpur Trioxide Hydration Using Vanadium Catalyst Semantic Scholar

Cstr Vs Pfr Differences And Performance Equations Youtube

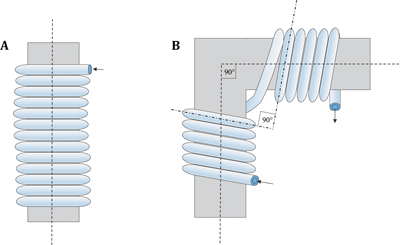

A Coiled Flow Inversion Reactor Enables Continuous Processing

Schematic Design Of Plug Flow Reactor Pfr And Continuous Stirred Flow Download Scientific Diagram

Design By Modelling Features The Chemical Engineer

Tubular Reactor The Ultimate Faq Guide Filson Filter

Flow Reactors Tri Flo Continious Flow Reactors Micro Reactor Mumbai India

Gate Ese Design Of Ideal Batch Reactor And Some Basics Of Plug Flow Reactor Offered By Unacademy

Laboratory Experiment Residence Time Distribution Cascade Chemgapedia

Notes Introduction To The Descriptive Equations For Chemical Reactors Altamira Instruments